Fretting and Reciprocating Sliding Tester

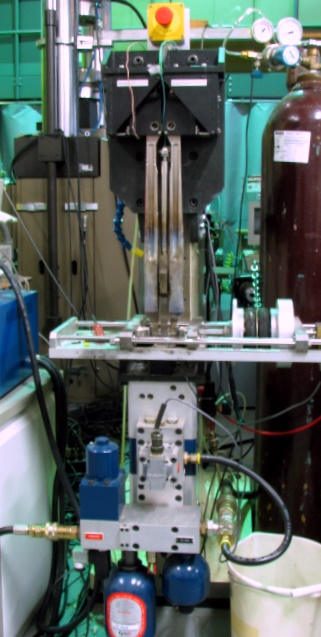

This facility includes a Phoenix Tribology Ltd. DN55 High Temperature Fretting Machine. This equipment is unique in that the maximum normal force that can be applied is 4500 N, which is considerably higher than conventional fretting machines. Oscillating frequencies up to 400 Hz may be controlled under fretting conditions (< 400 microns of cyclic displacement). The system can also perform reciprocating sliding with maximum stroke of 20 mm at 5 Hz, allowing fretting wear experiments to be also conducted. The servohydraulic actuator is closed-loop computer controlled. Complex waveforms may be programmed. All measured test variables are stored through high speed computerized data acquisition.

The moving specimen carrier is designed to hold a ball or roller of 20 mm diameter in a given mode of point, line or area contact. The fixed specimen tooling comprises two forks, each carrying a fixed specimen and loaded against either side of the moving specimen. This arrangement ensures that there are no significant out-of-balance forces acting on the moving specimen. Each fork reacts against its own independent piezo-force transducer, thus allowing the frictional force between the moving specimen and each fixed specimen to be monitored independently. This allows two different fixed specimen materials or contact geometries to be tested simultaneously under identical conditions of cyclic displacement, normal force, and temperature. Force is applied to the fixed specimen forks by means of a PID-controlled pneumatic bellows with force transducer feedback that potentially allows normal force to vary during a cycle. The loading system is mounted freely on a horizontal linear slide, allowing the fixed specimens to self-center on the moving specimen. An electrically-fired furnace allows the test to be run at temperatures up to 800°C.

In addition, fretting fatigue experiments can be conducted on any of the servohydraulic test systems previously described using a bridge-type fretting apparatus clamped onto a fatigue specimen. Both cylindrical-on-flat (line contact) and flat-on-flat (area contact) configurations can be employed. Friction force is measured using a calibrated strain gage on the fretting pads.